-

United Safety & Survivability Corporation

101 Gordon Drive

Exton, PA 19341, United States - 610-265-3610

- info@shoxs.com

You have no items in your cart, add some on the products page.

This problem was recognized by scientists from major fleet agencies, and dedicated steps were taken to design seat testing requirements and standards. The goal was to create an apples-to-apples comparison between shock mitigating seats to assess performance. Maritime agencies would now have a way to measure how well a seat mitigates impact with a straightforward mathematical calculation.

The resulting tests, published by the United States Navy and widely recognized as the industry standard, require careful measurements in a controlled environment.

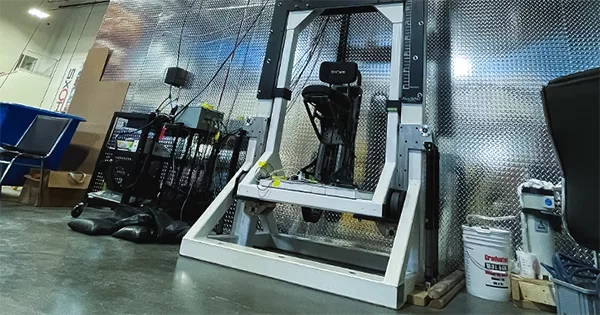

The performance tests require that suspension seats are attached to the deck of a drop-test rig loaded with weights to simulate a human occupant. The weighted seats are then then dropped to the floor.

Data from accelerometers attached to the seat is filtered and processed to determine the seat’s response in a manner relevant to human health.

The same calculation is performed for the acceleration measurements made on the deck, and the two results are compared to see by how much the seat has reduced the impact severity.

The test recommendations also include impact severity assessment algorithms and standardized reporting formats that allow for direct comparison between competing products.

Allsalt Maritime has taken a measurement-driven approach to the problem of comparing marine shock mitigation seat performance. The Allsalt Innovation Centre, based in Victoria, British Columbia, features a drop test rig in the research and development lab for assessing the performance of seats under various conditions and loads.

Allsalt's technical team continues to hone the company's approach to the science of shock mitigation.

Our mission is to transform the moment of impact into a safer experience for all who work or play on the water.